The Significance of Cement in Construction Industry

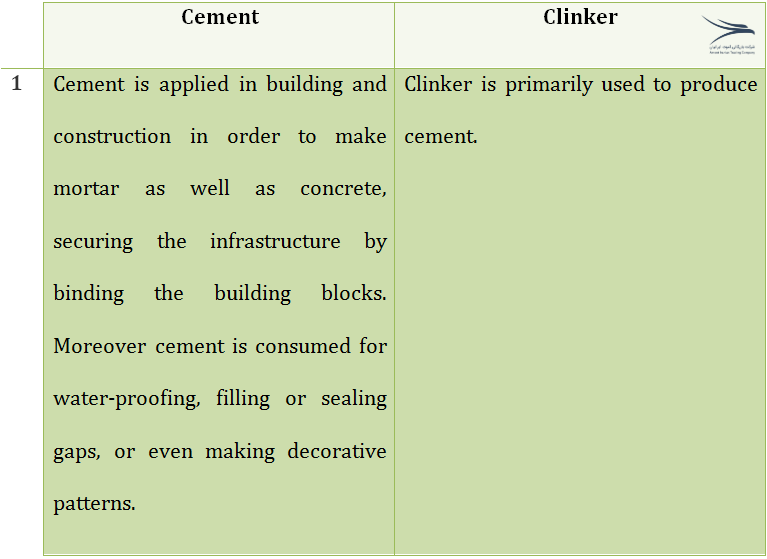

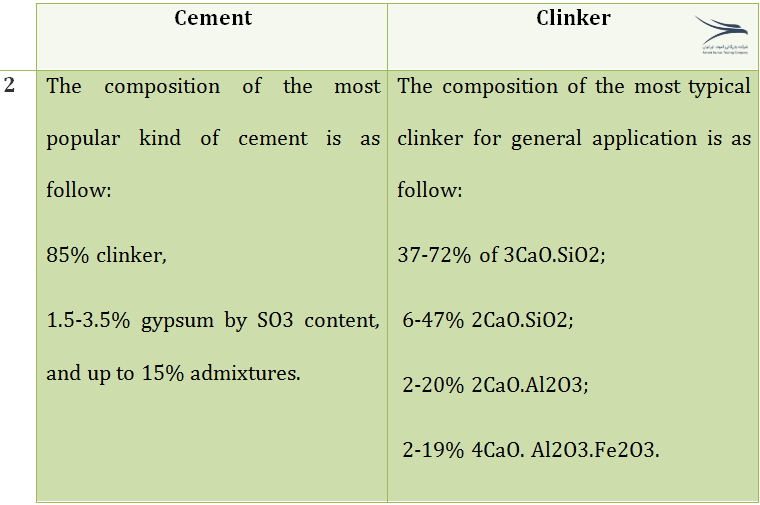

Cement is known as the world’s most important building material, replacing all other substances like clay and lime. Cement is dry powder and should not be confused with concretes or mortars. However cement is an important constituent of both of these materials, acting as ‘glue’ which gives strength to structures. Some construction trade items that include cement are as follow: plain cement concrete, reinforced cement concrete, mortar, plaster, grouts, paints and in pre-cast elements. Why cement is highly consumed and accepted universally as the world’s most significant building material? The answer is explained bellow:

- Cement is several times stronger than lime and clay.

- If it is stored properly in ordinary atmosphere, it does not deteriorate for a long time (at least 3~4 month).

- When cement is mixed with water, begins setting fast and gets sufficient strength in a day or two, but other binding materials require much longer time. Hence cement boosts the speed of construction.

- Cement strongly withstands compressive pressures well. Where tension appears, cement can give good bond to steel reinforcement and transfers the surplus pressures to steel.

- Cement can be manufactured in large volumes in controlled condition, packed and transported.

- Cement is made from some materials like limestone, hematite, bauxite, clay and etc. which are abundantly available in the upper crust of the earth.

- Cement imparts durability and stability to other building elements.

- Cement is comparatively a cheaper and more affordable substance.

- Cement can be mixed and applied at will with locally available materials at site.

Amoot Iranian Trading Company had started its business as a mineral and chemical supplier, exporting iron ore, sulphur fertilizer and urea fertilizer to various countries. Amoot’s next step was in agro industry, supplying fresh and dried fruits, especially Mazafati date of Iran for international buyers.

Amoot successful background, its customer oriented style and the valuable experience in mineral, chemical and agro industries have appreciated us to strongly expand the scope of Amoot activities in order to meet different customers’ requirements as best as possible, hence we have developed our business and added the world’s most important building material, cement, to our product list.

We have given new strength to the construction industry and helped the infrastructure development by supplying high quality Iran cement. “Amoot” name is shining as an experienced trading firm, dealing as an iron ore, urea, sulphur and date supplier as well as cement and clinker supplier. We are inviting all potential customers who are searching for a trustworthy cement supplier and clinker supplier to call or message our experts for any further details.

Iran cement and Iran clinker are welcomed by international purchasers and on 2018 Iran cement exports trended up 10.2 pct. in 7 months (March 21-Oct. 22). More than 7.65 million tons of Iran cement and Iran clinker had been exported in seven months. Amoot Iranian Trading Company as a reputable cement supplier and clinker supplier is eagerly ready to combine the highest quality of Iran cement and clinker with the best price for any buyer searching an experienced famous cement and clinker supplier in Iran.

how has cement impacted society today

importance of concrete in civil engineering

different types of cement and their uses in construction industry

types and properties of cement